Tailored control technology for biogas plants

Automation and efficiency on an industrial scale

TEWE uses programmable logic controllers (PLC) to precisely control and automate processes in biogas plants. These PLC systems are specially configured and programmed in-house to customise them to the specific demands of each individual plant. At TEWE, our highly developed electronics and control systems are one of our main areas of expertise. They maximise efficiency and ensure the operational safety of every plant.

Fundamentals of PLC control

The PLC control system is developed using proven programming languages such as Ladder Logic (ladder diagram), Structured Text (ST) or Instruction List (IL) and adapted to the specific processes of the biogas plant. Inputs (sensors, switches) and outputs (motors, valves) are precisely defined and validated using simulation and test tools. This ensures secure implementation and error-free operational control, which is a key benefit, particularly for complex industrial plants.

Technological partnerships and flexible system integration

TEWE works closely with leading providers of PLC technology to optimise control systems to the needs of the biogas plant:

- Siemens: Models such as the S7-1200 and S7-1500 are programmed via the TIA portal, which centralises all aspects of automation and enables flexible control.

- Rockwell Automation (Allen-Bradley): Systems such as ControlLogix and CompactLogix, programmed with Studio5000 software, offer a reliable alternative for industrial control systems.

The choice of PLC technology depends on the requirements of the plant in question, as well as regional support and availability. The Siemens TIA Portal provides a comprehensive, integrated software environment that is particularly suitable for the efficient and flexible automation of biogas plants.

Integrating AI into PLC systems

TEWE integrates AI into PLC systems to further optimise the control systems. These AI-assisted functions help biogas plant operators maximise the efficiency and service life of their plants:

- Predictive maintenance: The AI analyses operational data to identify when maintenance will be required ahead of time, thus reducing downtimes.

- Process optimisation: Continuous data analysis allows processes as well as the overall performance of the plant to be improved.

- Anomaly detection: By detecting anomalies in real time, the AI identifies potential problems and inefficiencies before they can impact production.

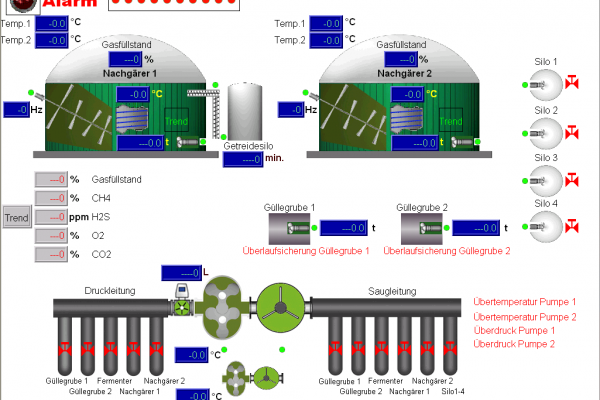

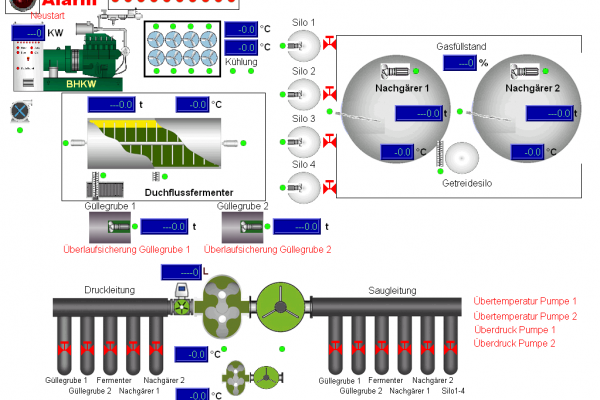

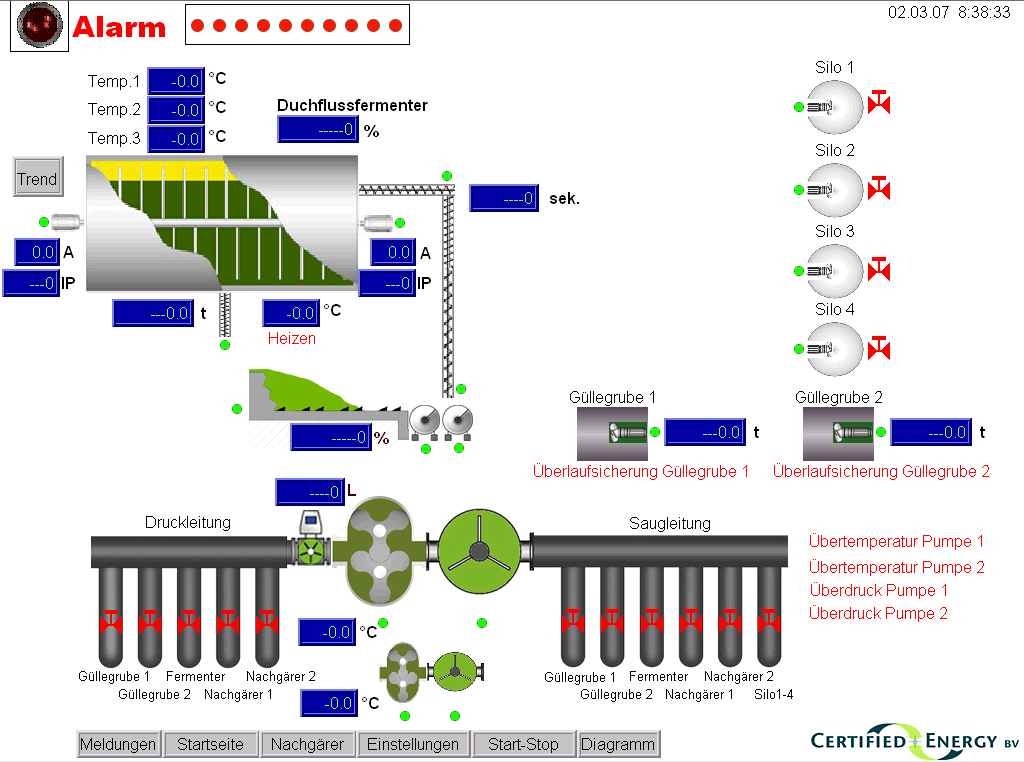

Modular software solutions for biogas plants

Building on over 20 years of experience, TEWE develops software solutions which are intuitive to operate and easy to install. The modular programs are easy to parameterise and guide the operator through the entire process. Simple symbols and traffic-light colours give clear information on the status of the plant and optimisation recommendations to improve user-friendliness.

Flexibility marketing software for flexible energy feed-in.

TEWE also offers specialised flexibility marketing software which optimises the trade of electrical energy and enables operators to flexibly adapt electricity production to market conditions:

- Flexibility: The software enables operators to feed in electricity at current market prices and thus operate with maximum economic efficiency.

- Load management: The control adapts electricity production and price developments to the energy market to ensure cost-effective operation.

- Access to markets: With integrated interfaces to commercially available platforms, the flexibility marketing software makes it easier to access marketplaces and coordinate marketing.

Operators benefit from this flexibility thanks to the economic advantages it provides, while at the same time contributing to grid stability – a valuable addition for the energy sector and for companies that rely on flexible and optimised electricity production.

References